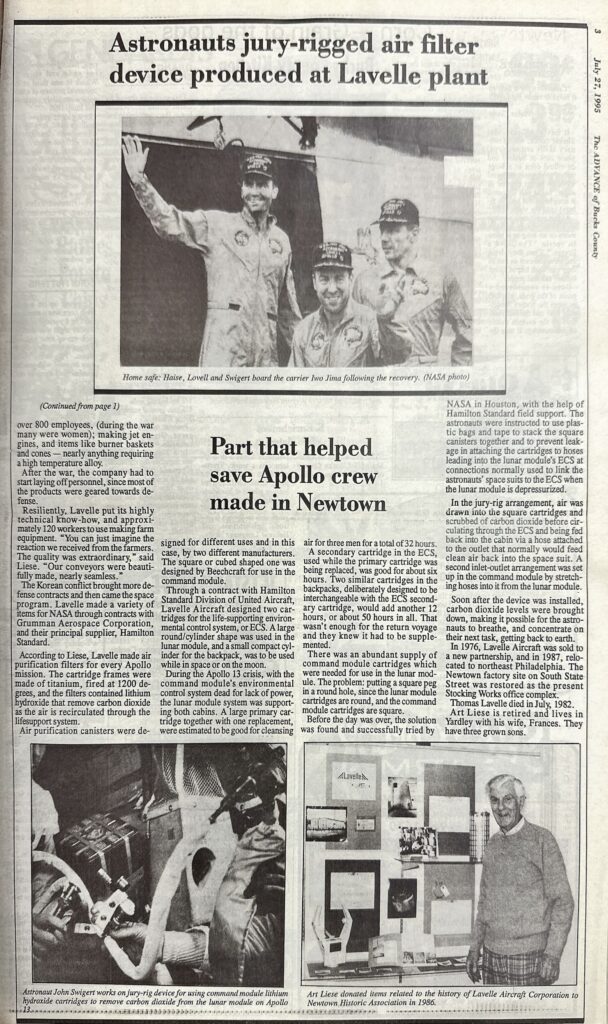

They Weren’t on the Rocket—But They Saved the Mission

When Apollo 13 suffered a catastrophic explosion en route to the Moon, the world held its breath. Oxygen was leaking. Power was draining. And carbon dioxide—the astronauts’ own breath—was building up inside the Lunar Module.

If NASA couldn’t scrub the CO₂ fast enough, the astronauts would suffocate.

So engineers on Earth worked furiously, piecing together an improvised fix using duct tape, plastic bags, and hose tubing. It became one of the most iconic moments in space history.

But hidden in that story is another hero:

Lavelle Aircraft Corporation, a small subcontractor from Pennsylvania, that built the original canisters that made the fix even possible.

Who Was Lavelle Aircraft Corporation?

Located in Bucks County, PA, Lavelle wasn’t a household name. They weren’t Lockheed or Boeing. They didn’t launch rockets.

But they were masters of precision aerospace components, and by the late 1960s, they were quietly supplying NASA with key parts for missions like:

-

TIROS and Telstar (early communications satellites)

-

Ranger 7 (first close-up lunar images)

-

And critical life-support components for Apollo, including…

The lithium hydroxide canisters used to remove carbon dioxide from cabin air.

These were the unsung lungs of every Apollo mission.

What Did the Canisters Do?

In space, oxygen is precious—but removing carbon dioxide is just as important. Humans exhale CO₂, and in a sealed spacecraft, it quickly becomes toxic.

The canisters built by Lavelle:

-

Contained lithium hydroxide, which absorbed CO₂

-

Were installed in both the Command Module and Lunar Module

-

Were lightweight, reliable, and mission-critical

-

Became the center of the Apollo 13 emergency workaround

“Without those CO₂ scrubbers—and a way to adapt them—the crew would have been in serious trouble.”

— Apollo 13 Flight Director Gene Kranz, paraphrased from mission transcript

How Did They Save the Mission?

The catch?

Apollo 13’s Command Module canisters didn’t fit the Lunar Module’s system.

So mission control needed to build a bridge between incompatible parts—on the fly, with only materials available onboard.

The canisters were good. The engineering was solid. But the real miracle was figuring out how to jury-rig a working scrubber using:

-

A plastic bag

-

A sock

-

Some duct tape

-

A cardboard cover from a flight plan manual

This makeshift filter was only possible because the Lavelle-built canisters worked exactly as expected. Without their precise build and reliability, the astronauts might never have made it home.

Key Takeaways

-

Lavelle Aircraft Corporation, based in Bucks County, PA, built the CO₂ canisters used on Apollo missions.

-

Their hardware was essential to life support and was at the center of the Apollo 13 rescue.

-

They contributed to other missions, including TIROS, Telstar, and Ranger 7.

-

Lavelle’s story is a testament to the importance of quiet subcontractors in high-stakes missions.

-

It’s a reminder that the Apollo program wasn’t just powered by astronauts—but by precision-built parts from local factories.

The Silent Lifesavers of Apollo

In Before The Moon, we shine a light on the unsung teams that made space history happen. From Warminster centrifuges to Lavelle’s canisters, these stories prove one thing:

🚀 The space race wasn’t won by a few. It was built by many.

✅ Learn more at BeforeTheMoonFilm.com

🔧 Follow us for behind-the-scenes space tech history: Instagram

📣 Share this if you believe every part matters.

Leave a Reply