What If the Most Important Computer in Space History Needed Philly to Get to the Moon?

When people think of Apollo, they picture Saturn V rockets, astronauts in white suits, and Houston’s legendary Mission Control.

But behind every lunar landing was a computer so advanced—and so small for its time—that it practically invented modern digital electronics.

And a huge part of that breakthrough ran through one place:

Philco-Ford.

Right outside Philadelphia.

Yes—the Moon landings depended on chips built in suburban Pennsylvania.

The Apollo Guidance Computer: The Brain of the Moonshot

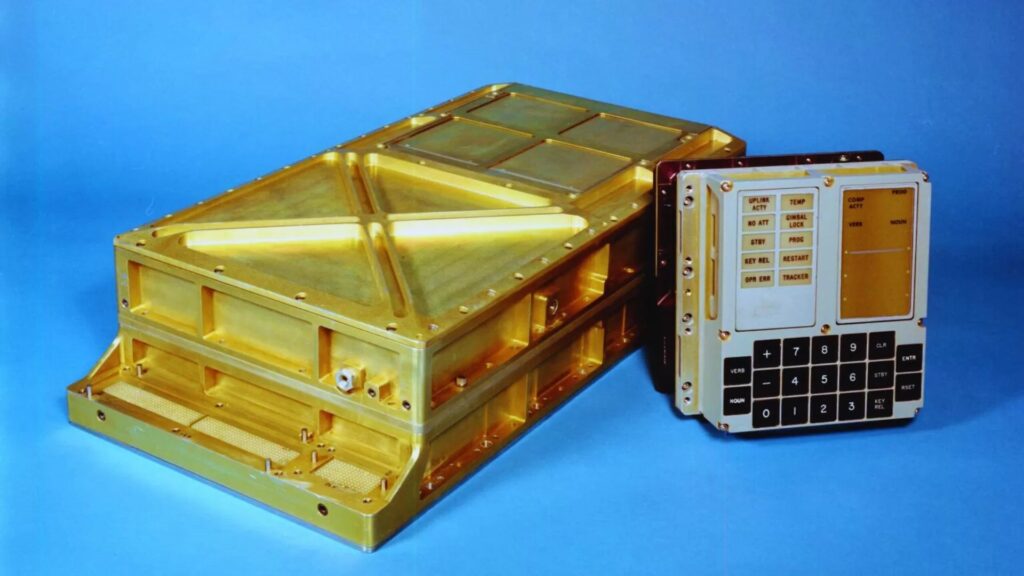

The Apollo Guidance Computer (AGC) was the first truly digital flight computer ever used for crewed spaceflight. Developed at MIT’s Instrumentation Lab and built by Raytheon, each Apollo mission carried two of them:

- One in the Command Module

- One in the Lunar Module

Each AGC handled:

- Guidance, navigation, and control

- Real-time trajectory and velocity calculations

- Engine burn timing

- Astronaut inputs via the iconic DSKY display

All this with just about 38,000 words of fixed memory and 2,000 words of RAM—roughly 72 KB by modern standards.

There was no redundant AGC on board, and no room for error.

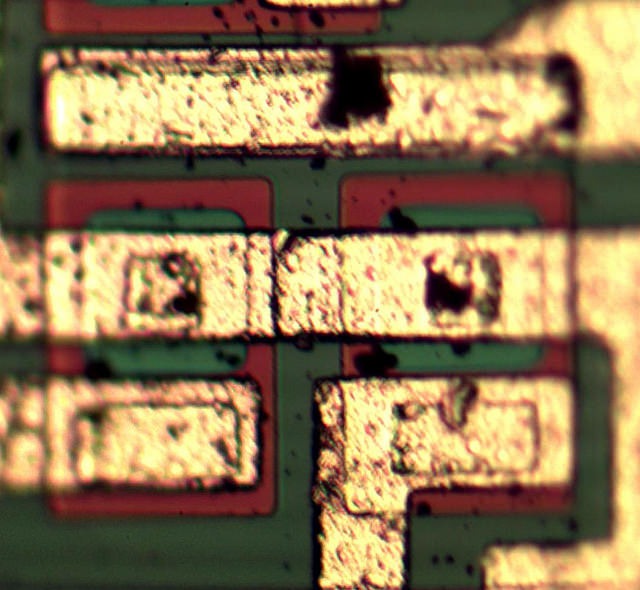

Inside this miracle of engineering were thousands of integrated circuits—tiny silicon chips that powered the AGC’s logic. And to build them, NASA needed manufacturers with world-class reliability and precision.

That’s where Philly entered the story.

Philco-Ford: The Quiet Giant Behind Apollo’s Microchips

Years before the microprocessor revolution, Philco (later Philco-Ford) transformed a former radio and TV brand into a powerhouse of military and aerospace electronics.

Their facility in Lansdale, Pennsylvania, became one of the nation’s premier producers of early integrated circuits.

Fairchild Semiconductor, which designed the logic used in the AGC, licensed its NOR-gate family to Philco, making Philco a major second-source supplier of the ruggedized ICs that NASA demanded.

Why this mattered:

- Apollo needed hundreds of thousands of reliable, flight-qualified chips

- Fairchild alone couldn’t meet production demand

- Philco’s manufacturing quality was so high that they produced a significant share of the chips used in the Block II AGCs that flew the Moon missions

In short:

The computer that took humans to the Moon ran on silicon built in suburban Philadelphia.

That’s a piece of history most people never hear.

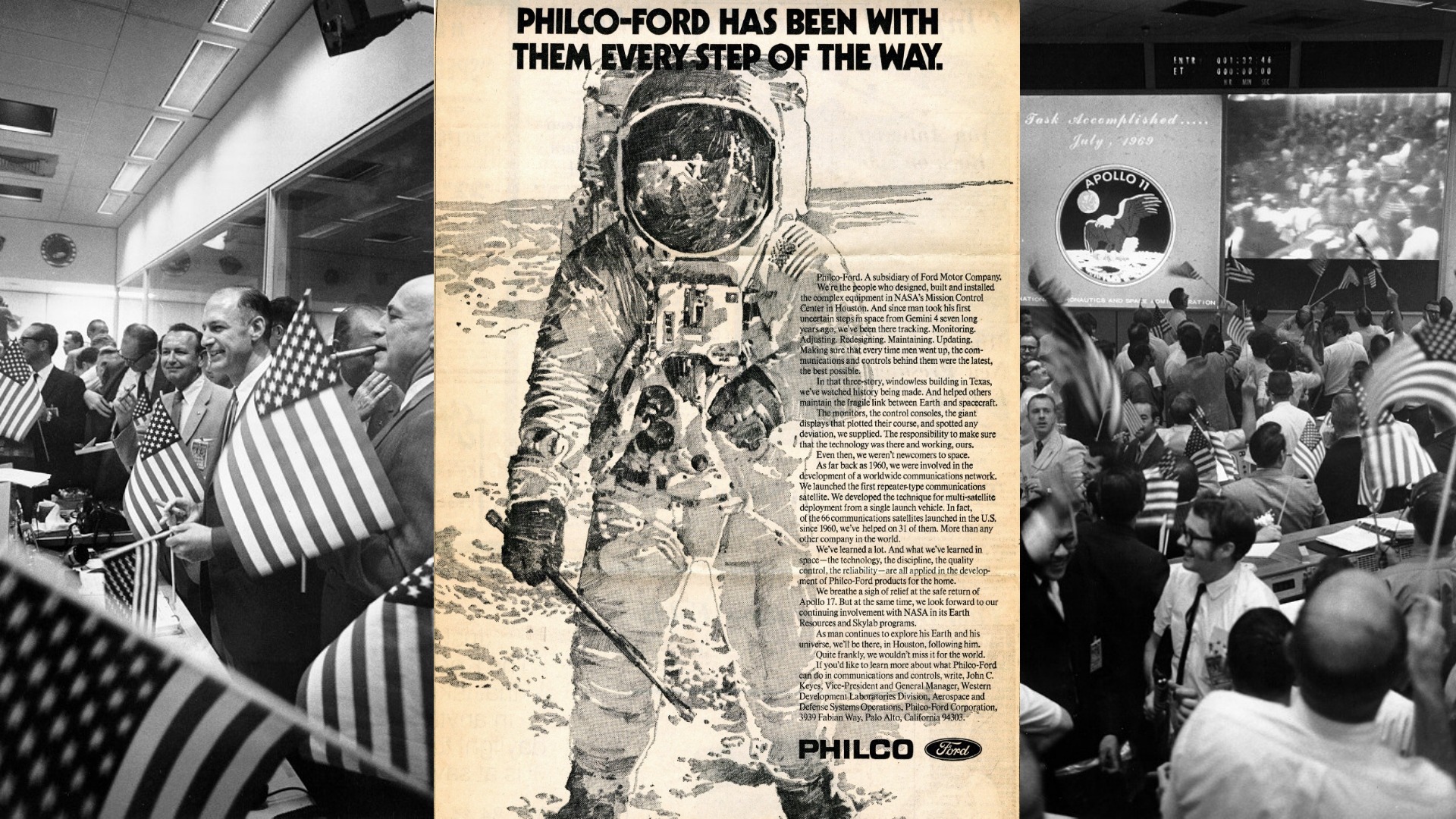

Philco-Ford Also Helped Build Mission Control

If you watched Apollo 13, For All Mankind, or any real footage from Houston’s Mission Control, you’ve seen Philco’s work.

Philco-Ford’s Houston Operations Division designed, engineered, and maintained the consoles inside both Mission Operations Control Rooms (MOCRs) at the Johnson Space Center.

These consoles:

- Routed real-time telemetry

- Displayed spacecraft data

- Managed voice communications

- Linked flight controllers to the IBM mainframes in the Real-Time Computer Complex

- Served every mission from Gemini through Apollo, Skylab, Apollo-Soyuz, and into the early Shuttle era

Those blinking lights, those rows of switches, that iconic green font glow—

that was Philco.

And because Philco-Ford was a Pennsylvania-based company, Houston’s nerve center of human spaceflight was, in a very real sense, running on Philly DNA.

Simulation, Training, and the Human Story

Philco-Ford didn’t write the flight software that ran aboard Apollo—that was MIT.

They didn’t run the big trajectory computers, either—that was IBM.

But Philco-Ford did play a major role in the systems that made Mission Control work:

- Display formatting

- Real-time data routing

- Controller training simulations

- Console logic and interface updates

- Communications and system integration support

When flight controllers trained for emergencies, they used Philco-supported simulation environments.

When they monitored spacecraft telemetry during a burn, they watched it through Philco-designed displays.

Philco weren’t the rock stars of the Apollo story.

They were the crew behind the crew, the engineers who stitched NASA’s giant digital nervous system together.

Key Takeaways

- Philco-Ford’s Lansdale, PA facility manufactured a large share of the integrated circuits used in the Apollo Guidance Computer.

- Philco-Ford designed and supported the Mission Control consoles used from Apollo through the early Shuttle era.

- Their engineers helped power the displays, communication links, and simulations that made Mission Control possible.

In other words:

The space race wasn’t just launched in Florida and controlled from Texas—

it was built, in part, in Pennsylvania.

From Silicon to Liftoff

In our film Before The Moon, we trace the hidden connections between small towns, forgotten factories, local engineers—and the most daring exploration in human history.

Philco-Ford’s contribution is one of those stories:

a story of quiet excellence, of precision manufacturing, and of Philly engineers who helped humanity take its first steps onto another world.

Want to help shine a light on these unsung pioneers?

- Visit: BeforeTheMoonFilm.com

- Follow: https://facebook.com/BeforeTheMoonFilm

- Share this story with anyone who loves tech, science, history—or Philly pride!

Leave a Reply